Chopper Frame Blueprints Pdf Download. Carranza Clinical Periodontology Pdf Download. Mini chopper plans free pdf The easiest frame to build is a traditional old school styled. Custom chopper frame plans pdf Free Download for Windows PDF- Convert, Inc. Word to PDF Converter Pro is the fast, affordable way to create PDF files.

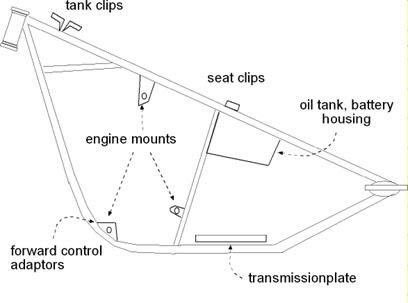

These plans are freely available from Crime Scene Choppers, they outline the construction of our frame jig as shown in Ron Covell's new 'Building a Chopper Chassis' video. Few of the dimensions or material callouts are critical. The width of part #6, the frame rail fixture, is determined by the ou tside width of your lower frame rails.

Typically, the inside width is 8 3/8', so the outside width is 8.375 + 2. the diamater of your frame tubing. Check the alignment of your parts carefully as you work, a warped jig is worse than no jig at all!

Crimescene Choppers JIG Plans - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Plans to big custom. These plans are freely available from Crime Scene Choppers, they outline the construction of our frame jig as shown in Ron Covell's new 'Building a Chopper Chassis' video. Crimescene Choppers JIG Plans - Free download as PDF File (.pdf), Text File (.txt). Chopper Frame Plans Drawing Advantage Summary. Stretched the down tubes about four inches over stock, the backbone two inches. Instructions are actually part of the material that used to accompany our.

7 8 6 5 4 4 6 5 4 3 3 3 3 3 1 2 1 2 ITEM NO. D E S C R I P T I O N L E N G T H 1 2 T U B E, R E C T A N G U L A R 3. 1 3 9 6 2 2 B A R S T O C K, R E C T A N G U L A R. 5 x 2 F l a t B a r 9 6 3 5 T U B E, R E C T A N G U L A R 3. 1 3 6 4 2 T U B E, R E C T A N G U L A R 3. 1 3 2 3 5 2 T U B E, S Q U A R E 2.

1 3 1 0 6 2 B A R S T O C K, R E C T A N G U L A R 0. 2 5 x 2 f l a t b a r 3 7 1 T U B E, R E C T A N G U L A R 3. 1 3 2 4 8 1 T U B E, R E C T A N G U L A R 3. Daniel johnston respect zip. 1 7 9 10 5 3 8 8 6 1 3 2 1/2' thick plate, 6' wide x 7' long with 2' x 3' rect.

Picture Frame Blueprints

Hole in center 6.000 7.000.750.750.500 Stitch weld 2' x.5' flat bar to 2' x 3' tube then set up in mill and machine a 1/2' slot for the length of the tube. P A R T N U M B E R D E S C R I P T I O N Q T Y. 1 N e c k F i x t u r e 1 2 S l i d e r M e c h a n i s m 1 3 B o l t P l a t e 1 4 H H N U T 0. 5 0 0 0 - 1 3 - D - N 1/2'-13 nut welded to top of #3 1 5 P i v o t P l a t e 1.75' x 1.75' square bar stock 2 6 N e c k P i v o t 1 7 a l l t h r e a d 3 / 4 ' - 1 6 t h r e a d e d r o d 1 8 N e c k C o n e 45 degree cone to hold steering neck 2 9 D K A - 1 3 R e i d T o o l 1 1 0 S D K A - 1 3 R e i d T o o l 1 I T E M N O. D E S C R I P T I O N L E N G T H 1 1 T U B E, R E C T A N G U L A R 2 x 3 x. 5 2 1 B A R S T O C K, R E C T A N G U L A R. 5 x 2 F l a t B a r 2 6.